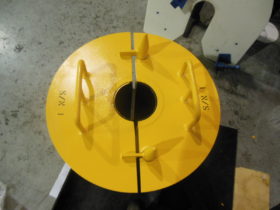

DTI has expertise in design and manufacturing of centralizes for SCRs, Flexible Risers and Umbilicals to aid in the installation process. The centralizer can be designed to be assembled on the SCR, Flexible riser or umbilical prior or post installation and the centralizers left on location to prevent damage to the outer sheath during the life of the Riser/ Umbilical.

Post-Installed Type Centralizers:

- Typically used with flexible risers and umbilicals on offshore floating facilities where I tube is discontinuous – such as on TLPs and Spars

- The advantage of installing centralizes after pull in are listed below:

- Centralizer installation is decoupled from riser/ umbilical pull in operations and can be completed off the critical path. As the installation can be performed with small ROV vessel, the installation cost can be reduced.

- As centralizers can be installed after the pull-in operation, the possibility of placing the centralizer in the wrong location due to inaccurate markings on the riser is eliminated.

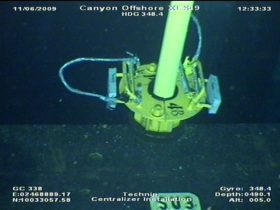

- Drop-in centralizers are two-part assemblies that are dropped into the top of the I-tube section typically on top of heave plates after riser is pulled in. The centralizers are designed for ease of installation and ROV compatible.

- Clamp-on centralizers are clamped on by the ROV and are typically at the bottom of soft tanks. Installation tools can be provided to assist in the installation of the clamp-on centralizer.

Pre-Installed Type Centralizers:

- Clamped on to the riser as it is over-boarded from the vessel.

- The analysis is performed for cathodic protection, installation loads, fatigue and other loading scenarios.

With in-house fabrication and coating capabilities, DTI controls all critical stages of execution from concept to delivery. Safety, Quality and On-time delivery are our main objectives when executing projects to meet our client’s expectations.