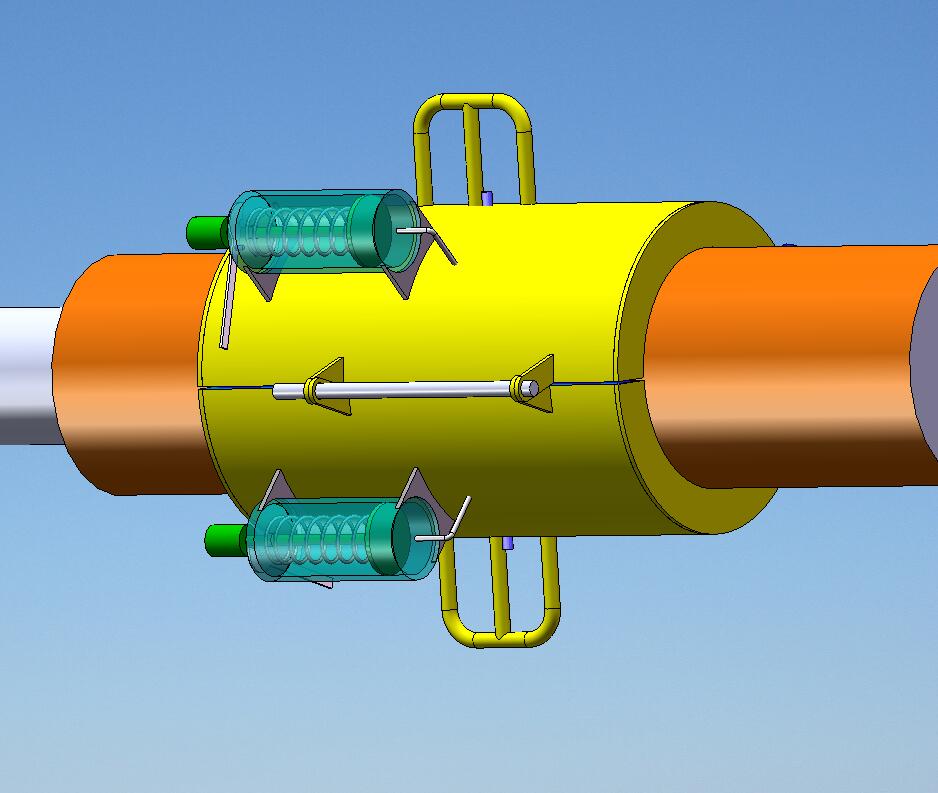

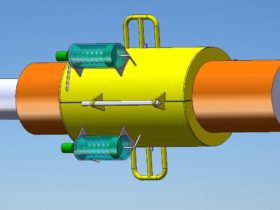

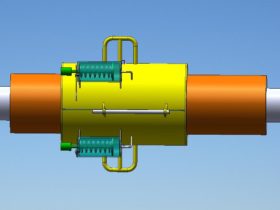

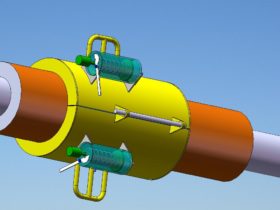

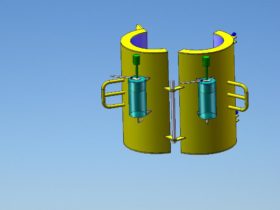

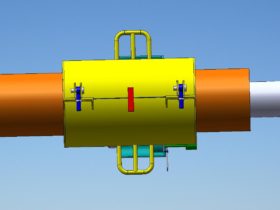

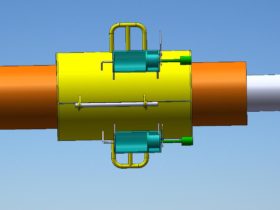

DTI has developed an innovative (patent granted) insulation repair system for subsea flowline, Jumper etc. The technology was initially developed for insulation of flowline connectors and was adapted for the wider application later on.

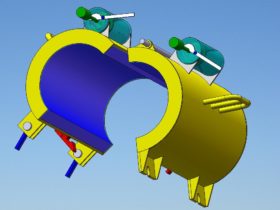

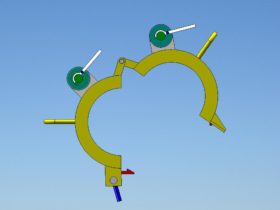

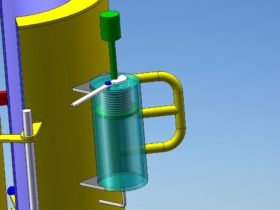

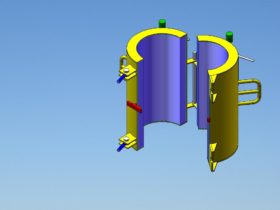

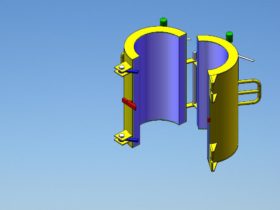

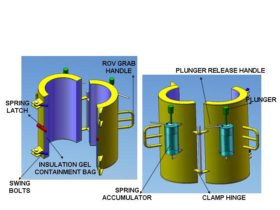

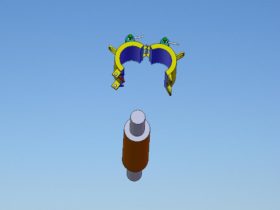

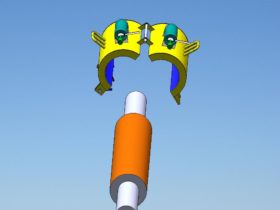

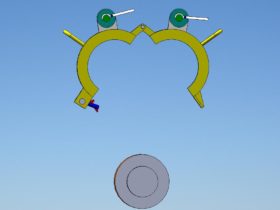

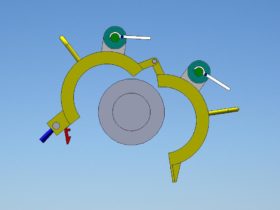

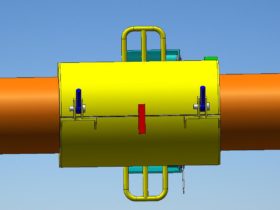

The insulation repair system consists of two-part ROV installable clamp with flexible bag into which insulating material can be injected with spring-loaded cylinders which store the gel. The insulation bag conforms to the shape of the pipeline when filled with the insulation gel under pressure. The gel in the bags functions as an insulator while positive pressure and contact of the bag with insulated surface ensures there is no connective heat loss by sealing flow paths.

Advantages of gel based insulation system designed by Deepsea Technologies, Inc.

- Superior insulation properties of the gel reduce the heat transfer.

- The pressure of the insulation gel/ liquid ensures the sealing bag makes contact on all surfaces of the pipeline ensuring increased thermal resistance as compared to conventional solid foam based method which shrinks upon installation subsea leaving venues of heat escape.

- Flexible bag ensures multiple sizes of piping can be accommodated with minimal change in design thus reducing the overall cost of the system.

- ROV compatibility and ease of installation reduces installation time.